HEAT EXCHANGERS FOR HOSTILE APPLICATIONS

<p class="MsoNormal"><span lang="EN-US">SVI Carbon

Pvt Ltd. has established its own sound technological and infrastructural base

to manufacture Graphite Heat Exchanger with various kinds of impregnation. Our

Heat Exchangers work have provided satisfactory service for critical and

hostile applications like Caustic solution, Sulfuric acid, Hydrochloric acid,

Metal salts, Chlorobenzenes, etc.</span><span lang="EN-US" style="font-size:18.0pt;

line-height:115%;mso-ansi-language:EN-US"><o:p></o:p></span></p>

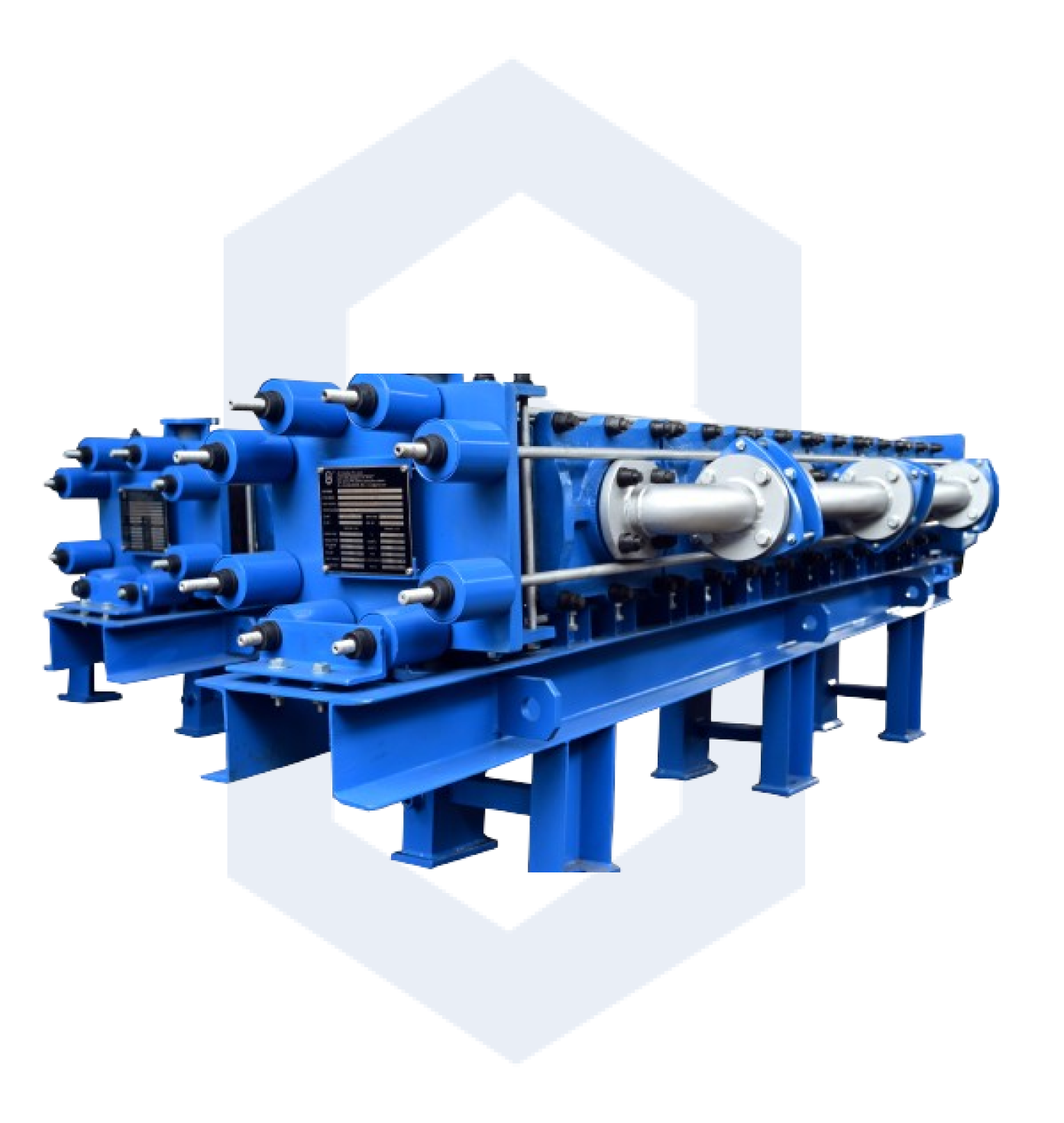

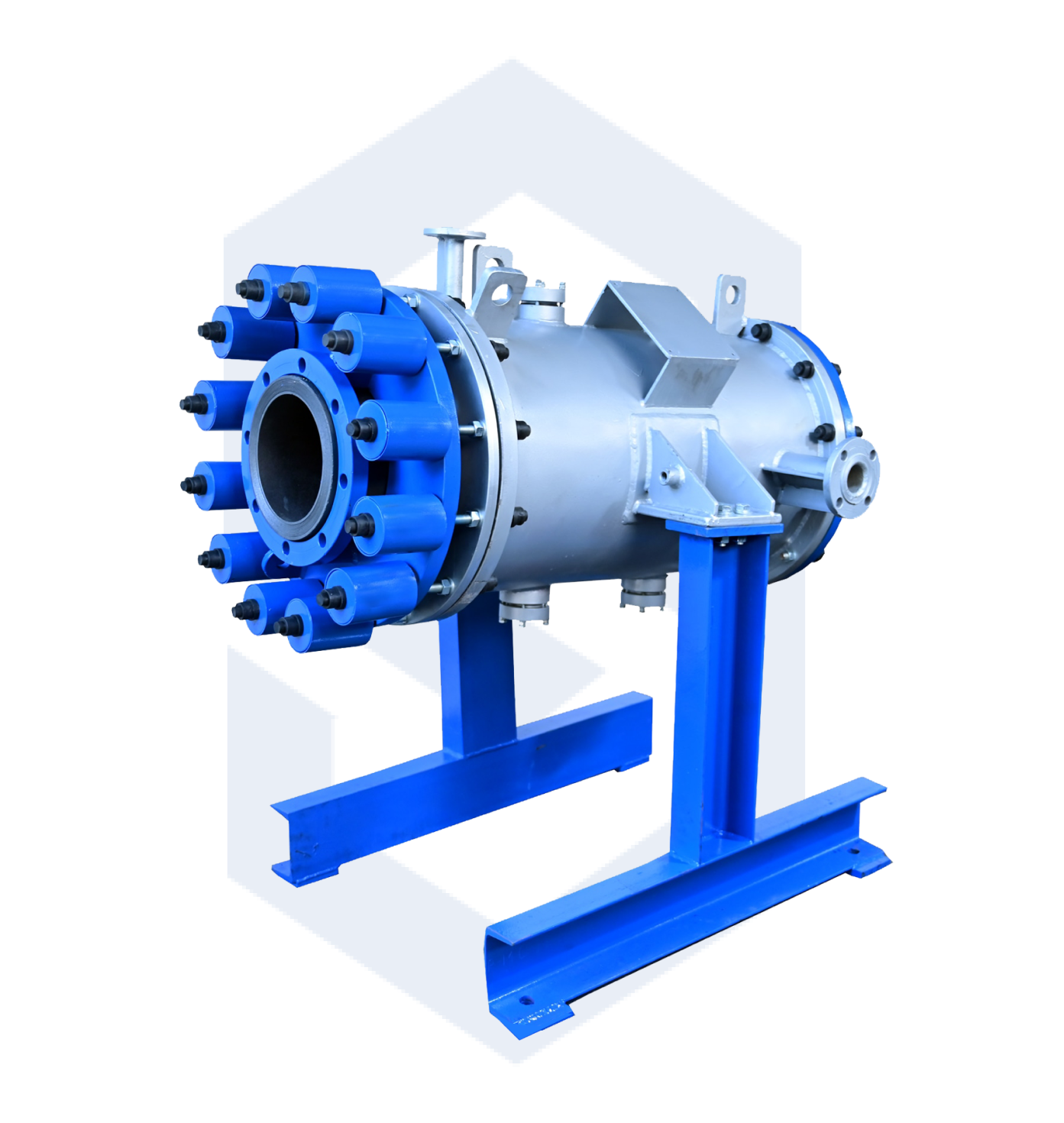

GRAPHITE BLOCK TYPE HEAT EXCHANGERS

<p class="MsoNormal" style="text-align:justify">SVICPL is a leading manufacturer of Impervious Graphite Heat and Mass Transfer Equipment. Renowned for high product quality, we are serving the Chemical and Steel industry for more than two decades in India and Overseas. SVICPL can design and manufacture in compliance with Indian Standard, ASME design codes, ‘CE’ marking as per PED. Our Heat Exchangers are compact and reliable, while complying with the mechanical strength parameters, that exceed the values specified by ASME. Our customers rely on our products because they are backed by technocrats having extensive experience of more than 25 years in this industry.<br></p>

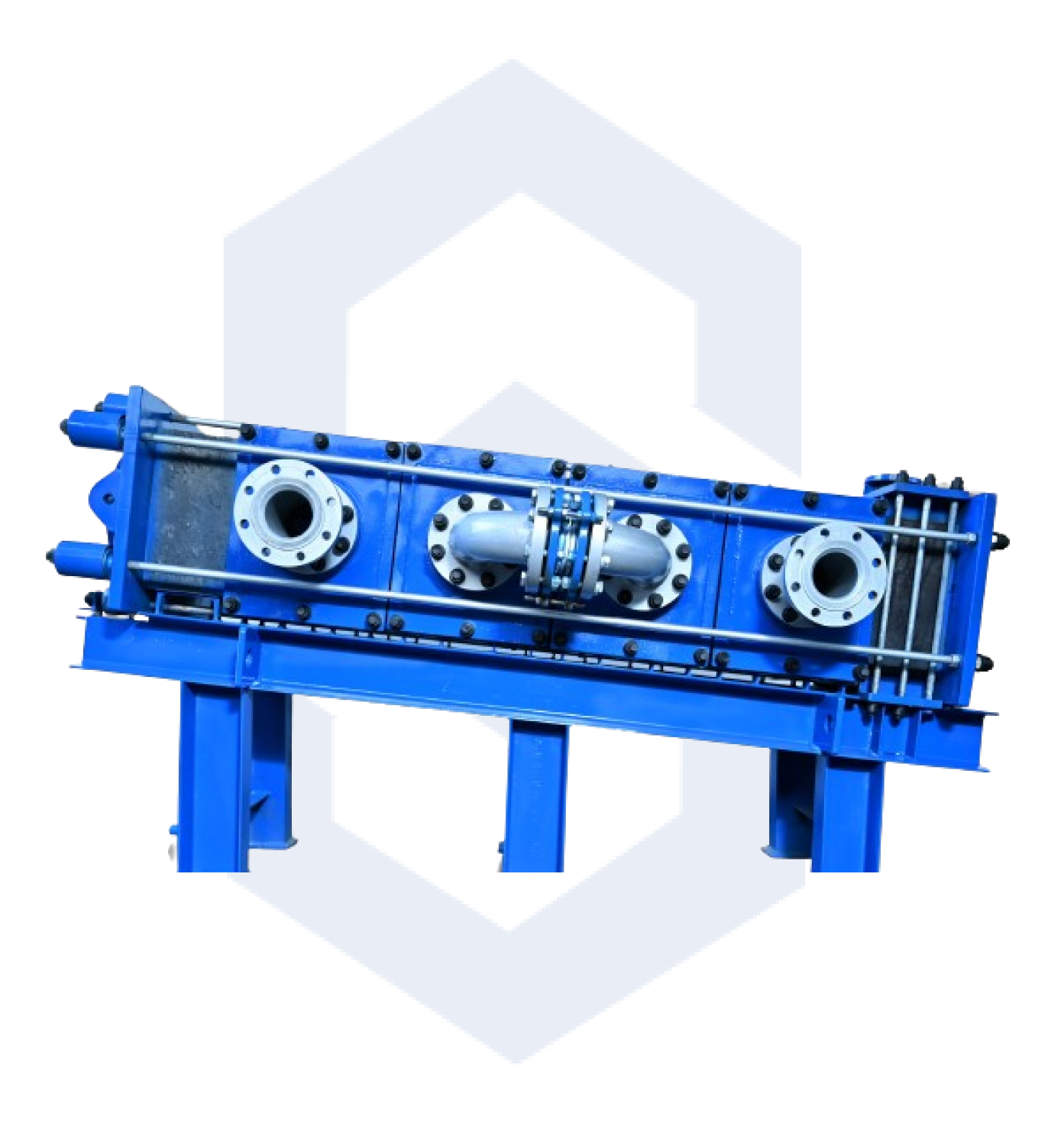

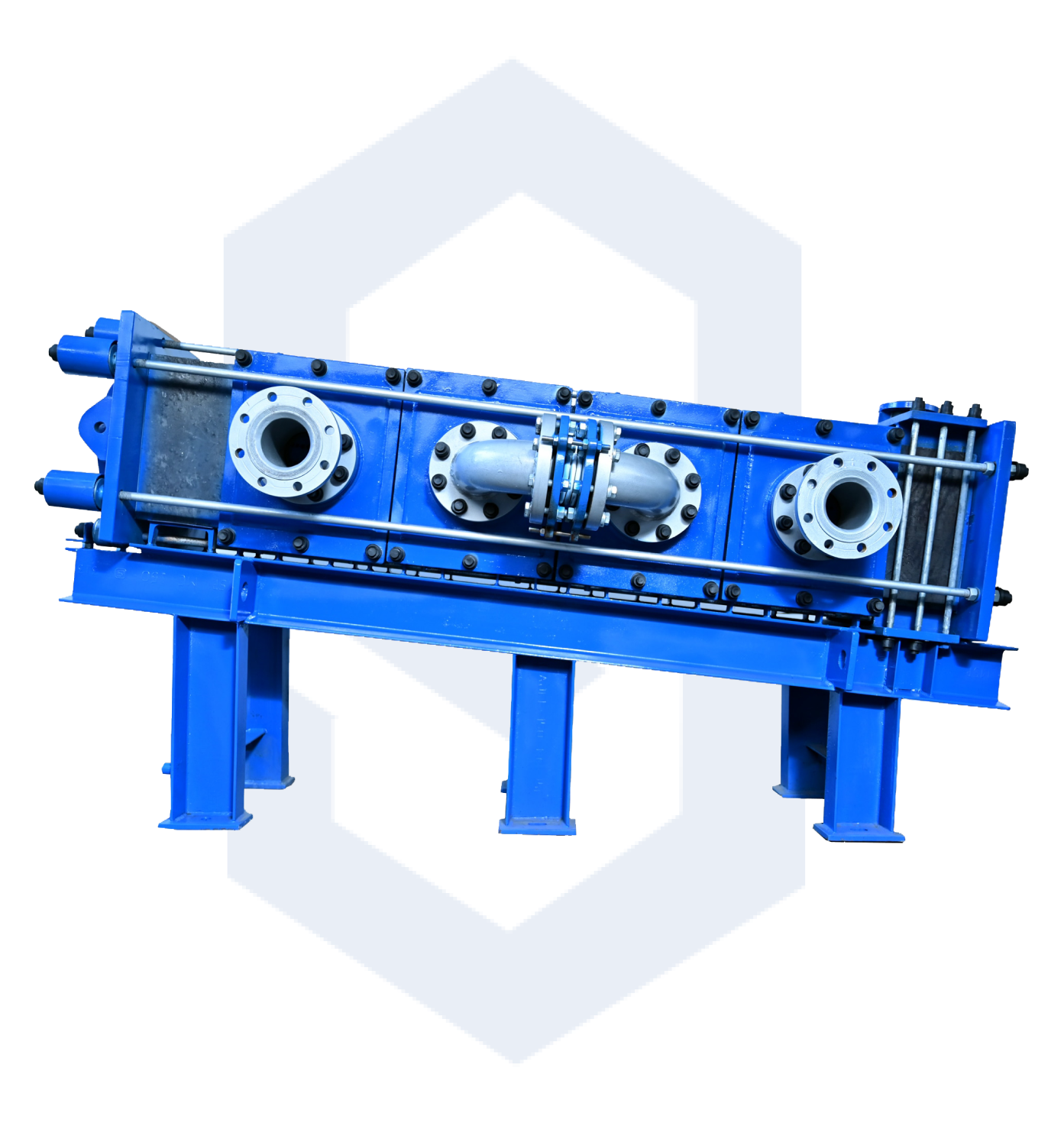

DUAL UTILITY CONDENSERS

<p class="Default"><span lang="EN-US" style="font-size:11.0pt;mso-ascii-font-family:

Calibri;mso-ascii-theme-font:minor-latin;mso-hansi-font-family:Calibri;

mso-hansi-theme-font:minor-latin;mso-bidi-font-family:"Times New Roman";

mso-bidi-theme-font:minor-bidi;color:windowtext;mso-ansi-language:EN-US">SVI

Carbon Pvt Ltd. has developed unique design of Dual Utility Condensers. It minimizes

the requirement of floor space and neutralizes the piping / fitting connections

between the outlet-inlet of the Primary to the Secondary Condensers. One

important salient feature of one design in Dual Utility Condenser is, it also

facilitates removal/separation of condensate from Primary condenser section

from the junction between the Primary and Secondary sections via the condensate

separator. In another design, vapors & condensate can be carry forwarded

with an Intermediate Block to the Secondary Condenser section. The performance

is exactly the same when compared with the conventional Primary-Secondary

Condenser assembly. <o:p></o:p></span></p>

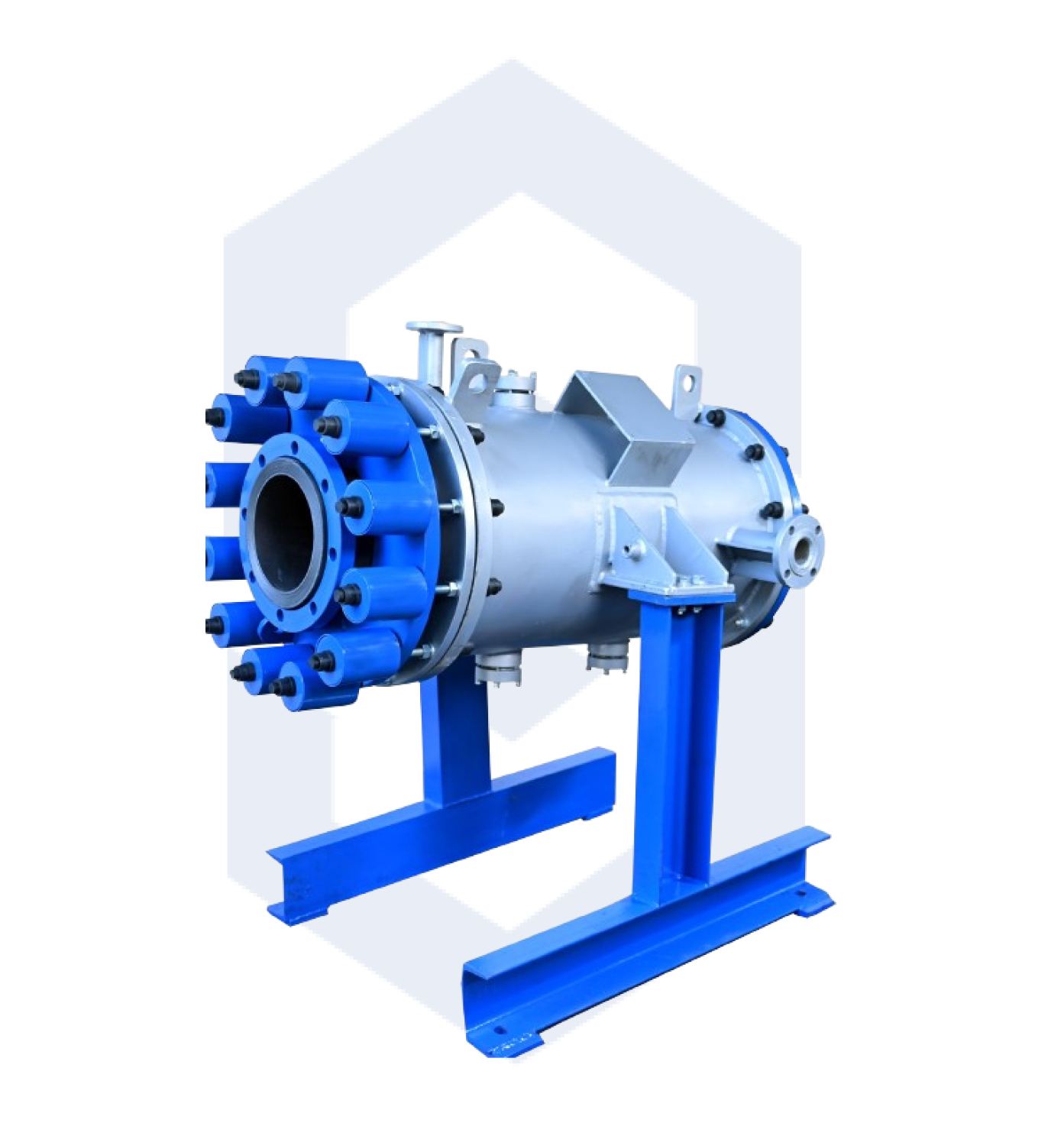

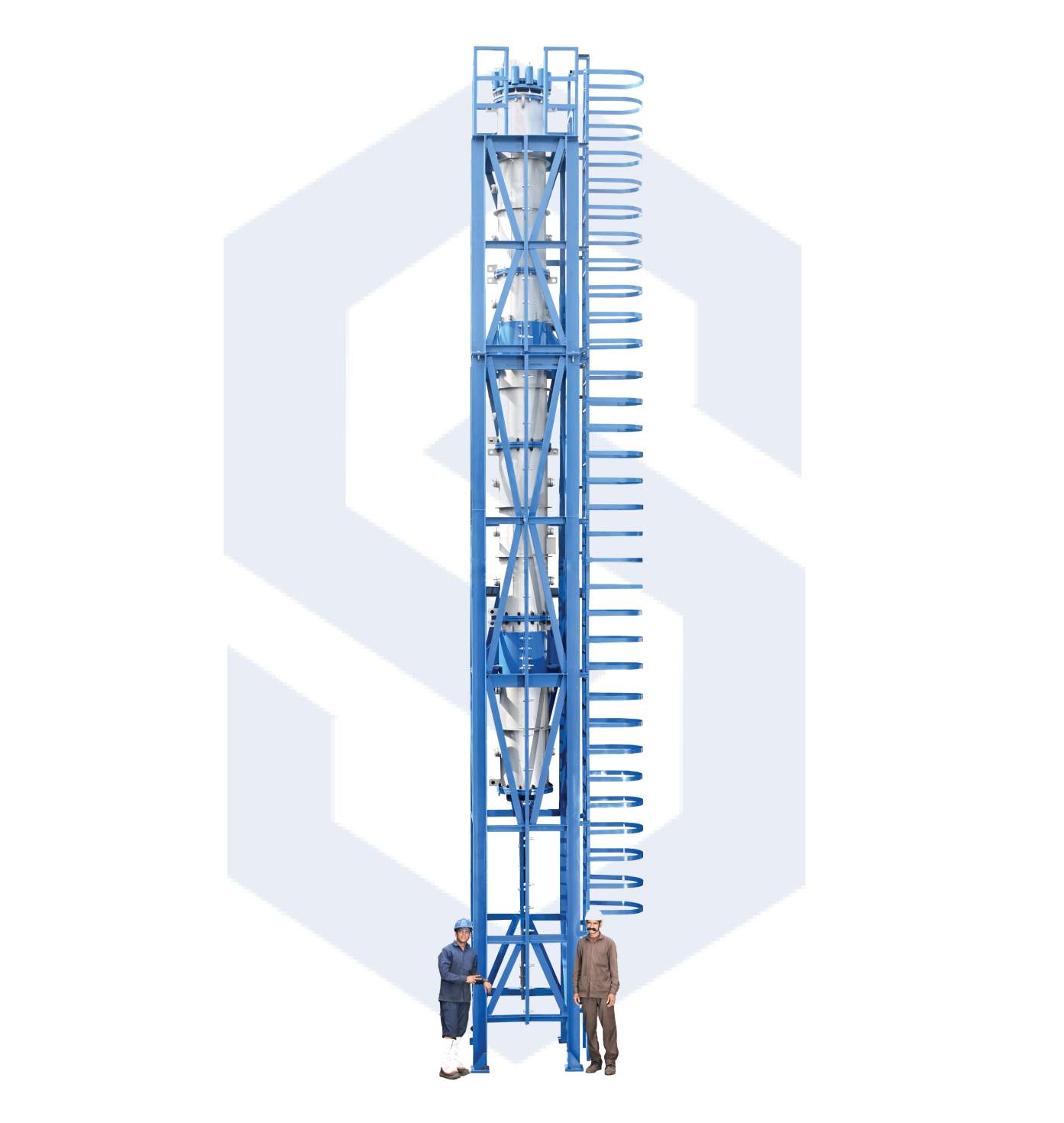

SMALLEST AND LARGEST GRAPHITE HEAT EXCHANGERS

<p class="MsoNormal"><span lang="EN-US">SVI Carbon

Pvt Ltd. has more than 120 Graphite Block Models. Appropriate block model is offered

to optimize the thermal design and floor spacing requirements. Largest Heat

Exchanger designed and manufactured by us has area of 108 sq.m. and height of 13

meters, whereas the smallest heat exchanger has an area of 0.3 and length 650

mm.<o:p></o:p></span></p>

GRAPHITE FALLING FILM ABSORBER, GRAPHITE FALLING FILM EVAPORATOR AND GRAPHITE PACKED BED SCRUBBER

<p class="MsoNormal"><span lang="EN-US">SVI Carbon

Pvt Ltd. designed Mass Transfer Equipments ensures maximum mass transfer between

the film or recirculating liquid and gas for enhanced as well as optimized performance.</span><span lang="EN-US" style="font-size:18.0pt;line-height:115%;mso-ansi-language:EN-US"><o:p></o:p></span></p>

GRAPHITE VACUUM JET EJECTOR SYSTEM (WATER, STEAM, CAUSTIC)

<p class="MsoNormal"><span style="font-size: 0.8125rem; font-weight: initial;">SVI Carbon

Pvt Ltd takes pride to present complete range of Vacuum Jet Ejector Systems. We

have ability to design multi-stage steam jet ejector systems, water or caustic

jet ejectors and also systems comprising of steam jet ejectors followed by

water or caustic jet ejectors. Salient feature of our ejector systems is their

high efficiencies, minimal utility fluid consumption. We can design,

manufacture and supply ejector systems for any given air leakage rate to

generate absolute pressure as low as 1 Torr.</span></p>

GRAPHITE RUPTURE DISCS (WITH HOLDER ASSEMBLY)

<p class="MsoNormal" style="margin-bottom:0cm;margin-bottom:.0001pt;line-height:

normal;mso-layout-grid-align:none;text-autospace:none">SVICPL designed Rupture Disc is compatible with most of the corrosive chemicals and possess mono-block type construction, due to which the installation can be done at ease. This also makes them the best choice for low and intermediate burst pressure ratings. SVICPL offers wide range from 1 Inch to 12 Inch size that can also withstand full vacuum. Rupture Discs can be PTFE or Phenolic Impregnated. Due to our high volume manufacturing capacity, our Rupture Discs are very economical in price.<br></p>

GRAPHITE THERMOWELL

<p class="MsoNormal" style="text-align:justify"><span lang="EN-US">Graphite Thermowells of SVI Carbon Pvt Ltd.

make are reputed in the market for offering minimum thermal resistance, so that

temperature measurement error is minimal. They are excellent substitute to Stainless Steel and PTFE Thermowells. Thus, Graphite Thermowell of SVICPL are

an optimum solution; since it has good corrosion resistance associated with

minimal temperature measurement error due to high thermal conductivity of our

Genuine Graphite raw material. Our Graphite Thermowells can be supplied along with Stainless Steel, Graphite, Mild Steel flanges, as per the client's requirements.<o:p></o:p></span></p>